Hydroblasting is a game-changer in the world of industrial maintenance and cleaning as well. Expert hydro blast professionals lead the way, applying their knowledge to provide powerful and effective cleaning solutions. Cleaning condenser tubes is one area where hydro-blasting methods have proven extremely beneficial. Hydroblasting transforms the cleaning process using high-pressure water jets’ power, resulting in superior equipment performance, less downtime, and more overall efficiency.

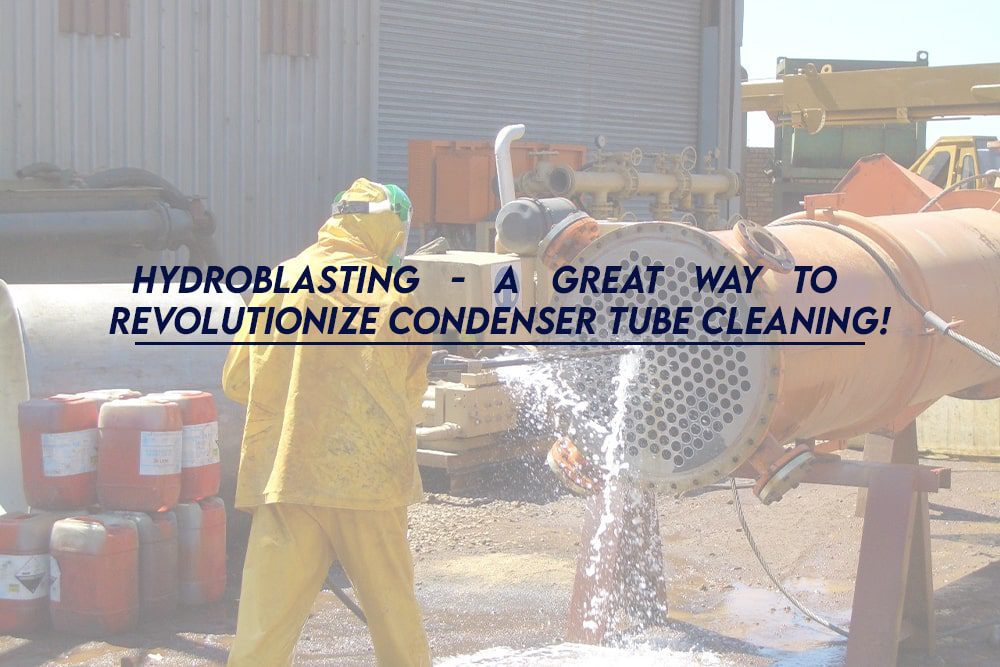

Hydro blasting – A Great Way To Revolutionize Condenser Tube Cleaning!

Hydro blast Technician – The Master Craftsmen:

Condenser Tube Cleaning – A Part Of Industrial Operations:

Hydro blasting: A Transforming Step Towards Condenser Tube Cleaning:

Unveiling the Hydroblasting Process:

Benefits Abound with Hydro blasting for Condenser Tube Cleaning:

Real-Life Applications Of Hydro blasting & Its Note-Worthy Success Stories:

1. Power Plants:

2. Industrial Cooling Systems:

3. HVAC Systems:

4. Petrochemical Industry:

5. Maritime Sector:

Crux:

In this blog post, we’ll delve into the world of hydro blasting, specifically the role of hydro blast technicians and the importance of hydro blasting in condenser tube cleaning.

Hydroblast Technician – The Master Craftsmen:

Hydroblast technician is a highly skilled individual who specializes in operating and maintaining hydroblasting equipment. They identify the complexities of high-pressure water jetting systems, such as the pumps, nozzles, and safety precautions. In addition, these specialists receive extensive training to guarantee that they can handle hydroblasting equipment safely and efficiently.

Hydro blast technicians are also skilled in assessing various cleaning needs. This assessment allows them to identify each work’s best pressure, flow rate, and nozzle selection. Their role is crucial to ensure the flawless implementation of hydro blasting techniques, providing worker safety and also effective cleaning results.

Condenser Tube Cleaning – A Part Of Industrial Operations:

Condenser tubes are essential for many industrial operations, including power plants and HVAC systems. These cleaning tubes accumulate deposits, including scale, biofilms, as well as fouling substances, over a period of time.

These deposits, if ignored, can reduce the effectiveness of heat transfer, raise energy consumption, and eventually cause equipment failure. Therefore, condenser tube cleaning must be done to maintain equipment performance and increase equipment longevity.

Hydroblasting: A Transforming Step Towards Condenser Tube Cleaning:

Due to its ability to provide targeted and powerful water jets, hydroblasting is an excellent choice for condenser tube cleaning. High-pressure water efficiently dislodges and eliminates deposits, restoring the effectiveness of the tubes.

Hydro blasting systems are adaptable to different tube materials and cleaning needs, making them a versatile cleaning solution. Moreover, hydro blasting prevents the necessity for chemical cleaners, lowering the negative ecological effects and safety concerns caused by chemical usage.

Unveiling the Hydro blasting Process:

Several crucial steps participate in the hydroblasting process. The hydro blast technician first evaluates specific cleaning needs, considering factors like tube material, deposit type, and thickness. Depending on this assessment, the technician selects the most appropriate water pressure, flow rate, and nozzle type.

The technician uses sophisticated hydro blasting equipment to drive high-pressure water jets into the condenser tubes, cleaning every tube in a controlled way. In order to achieve the best outcomes while protecting the tubes, the process can be customized to reach various levels of cleaning intensity.

Benefits Abound with Hydroblasting for Condenser Tube Cleaning:

When compared to traditional cleaning techniques, hydro blasting possesses many benefits. At first, the powerful water jets easily remove tough residues, providing a complete cleaning. Hydro blasting, unlike abrasive procedures, is non-abrasive, reducing the possibility of tube damage. Second, hydro blasting saves time by enabling faster cleaning cycles and minimizing equipment downtime. Third, the high-pressure water jets increase effectiveness with their quick cleaning. And finally, hydro blasting is a safer option since it reduces worker exposure to dangerous chemicals and fosters a more secure working environment.

Real-Life Applications Of Hydro blasting & Its Note-Worthy Success Stories:

Hydro blasting has been used successfully in a variety of real-life scenarios, demonstrating its efficiency and versatility. Let’s examine some noteworthy success stories where hydro blasting had a major influence:

1. Power Plants:

For effective heat transmission, power generation facilities significantly rely on condenser tubes. These tubes build up deposits over time, which causes performance to suffer and energy consumption to rise. In order to clean condenser tubes, optimize power generation, and restore their efficiency, hydroblasting has been widely used in power plants. It ensures continuous operation and decreases downtime by successfully eliminating deposits, resulting in significant cost savings.

2. Industrial Cooling Systems:

Cooling systems serve in a variety of industrial processes for maintaining appropriate operating temperatures. These systems frequently include condenser tubes susceptible to fouling, scale buildup, and biofilm formation as well. Hydroblasting has emerged as a popular method for cleaning these tubes, removing deposits thoroughly while ensuring ongoing heat transfer. As a result, industries improve the reliability and durability of their cooling systems by including hydro blasting in their maintenance programs.

3. HVAC Systems:

Heating, ventilation, and air conditioning (HVAC) systems are essential for comfortable indoor settings. Although due to clogged condenser tubes, the effectiveness of HVAC systems might deteriorate with time. What’s more, hydroblasting is an efficient and ecologically safe technique for cleaning these tubes, enhancing the HVAC system’s performance and increasing energy efficiency. Hydroblasting provides people with a comfortable environment and minimizes energy consumption, resulting in monetary savings for building owners.

4. Petrochemical Industry:

The petrochemical sector works with complex equipment and pipelines that must be cleaned regularly to ensure operational effectiveness. Hydro blasting has found widespread use in this industry, enabling the removal of hardened deposits, which include rust, scale, and residue. Petrochemical firms can efficiently clean equipment, prevent blockages, and enhance the manufacturing process by using hydro blasting processes. For the stringent cleaning needs of the petrochemical sector, hydro blasting is the best option due to its powerful impact and precision.

5. Maritime Sector:

Due to exposure to saltwater and marine creatures, cleaning demands for both ships and offshore platforms are nerve-wrenching. In the marine industry, hydro blasting has been extremely useful for cleaning ship hulls, decks, and other equipment. Hydro blasting increases the performance and longevity of maritime assets. It also assures compliance with ecological standards by eliminating marine growth, rust, and other deposits. Hydro blasting’s effective cleaning helps shipping firms work more effectively and save on fuel.

Crux:

Hydro blasting, enabled by a competent hydroblast technician transforms industrial condenser tube cleaning. The utilization of high-pressure water jets provides effective deposit removal, resulting in increased machine performance and lower energy consumption. In short, the adaptability, environmental friendliness, and time efficiency of hydro blasting make it an excellent choice for condenser tube cleaning.

Contact us